-

OUR ADVANTAGE

OUR ADVANTAGE -

OUR ADVANTAGE

OUR ADVANTAGE -

OUR ADVANTAGE

OUR ADVANTAGE

21

Years of

Passion & Experience

WELCOME TO OUR WEBSITE!

Tianshun Valve Industry Co., Ltd

Founded in 1993, after 21 years of development has become one of the large valve manufacturing base in Tianjin, China. The company specializes in the development of various valves, such as: butterfly valve, ball valve, globe valve, gate valve, groove valve, check valve, control valve, etc. Tianshun company factory production capacity reached 680000 sets, the products are exported to overseas customers, become highly welcomed by customers export products.

Our engineers continue to improve product quality and constantly develop new products to meet customer needs. We regard quality and service as the purpose of the enterprise and continue to work hard. At the same time, Tianshun Company cooperates with China National Petroleum Corporation, Wuhan Shipyard, Wuhu Shipyard, Tianjin Port Shipbuilding Heavy Industry and other well-known domestic enterprises all the year round.

Start1993 Year

· Registered capital of the company 5 million RMB

· The company covers an area of about 8000 square meters

· Production capacity reaches 680000 units

Products

Our engineers continue to improve product quality, and constantly develop new products to meet customer needs, we take quality and service as the purpose of the enterprise, and continue to work hard

Split knife gate valve, also known as split structure knife gate valve, is a knife gate valve with a split body design. Knife gate valve, also known as knife gate valve, is a valve that controls fluid flow by rotating knife gate. The split body design means that the body is divided into two parts, which are bolted or other fasteners together after fabrication to form a complete body.

View DetailsThe signal butterfly valve is a throttling device, especially suitable for high-rise building fire protection systems and other pipeline systems that need to display the valve switch status. It can adjust the flow of fluid by controlling the rotation Angle of the butterfly plate inside the valve body.

View DetailsAn electric actuator, also known as an electric actuator, is a driving device that provides linear or rotational motion. It uses electricity to drive and works under some kind of control signal.

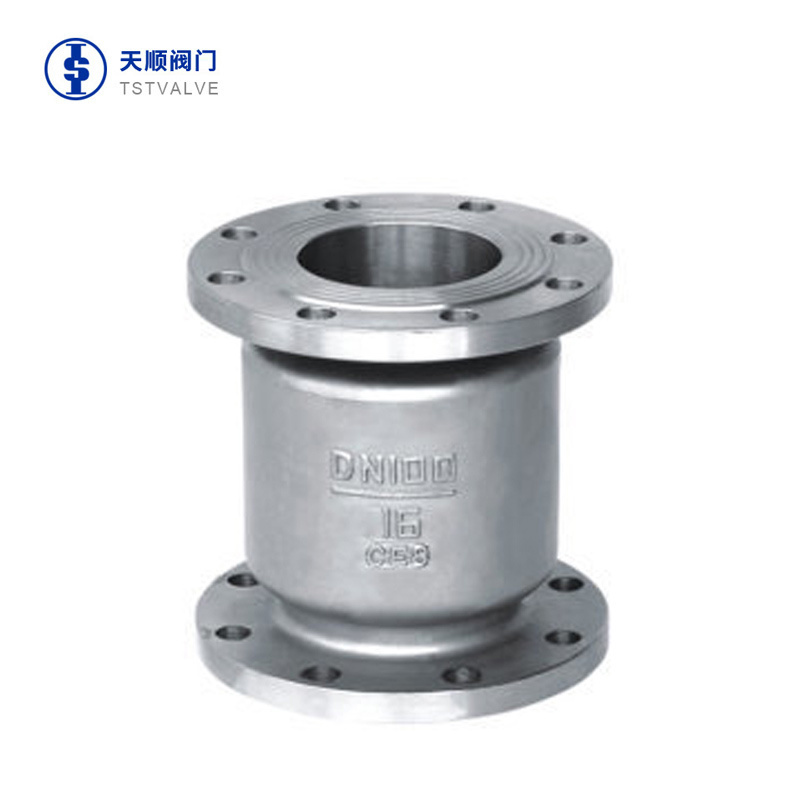

View DetailsThe vertical check valve works by overcoming the resistance of the spring through the medium pressure at the inlet of the pipe to open or close the valve. Specifically, when the medium flows downstream, the valve is opened by the thrust of the medium; When the flow direction of the medium is reversed, that is, when the pressure of the medium at the inlet is lower than the pressure at the outlet, the spring pushes the spool to the seat, so that the valve is closed and the medium is prevented from flowing back.

View DetailsSwing check valve is an important fluid control valve, which is mainly used to prevent the backflow of media in the pipeline. The working principle of the swing check valve is that when the pipeline fluid flows in the specified direction, the disc inlet pressure is higher than the outlet pressure, the disc is pushed away from the seat, and the valve is open. When the pressure difference between the two sides of the valve disc decreases to a certain level, the valve disc falls and returns to the closed state, preventing the backflow of the medium.

View DetailsThe clamp butterfly valve is an industrial product suitable for conveying various corrosive and non-corrosive fluid media pipelines in engineering systems, mainly used to regulate and cut off the flow of media.

View Details-

Video

Our company specializes in the development of various valves, such as: butterfly valves, ball valves, globe valves, gate valves, trench valves, check valves, regulating valves and so on.Know More + -

Product View

Our engineers continuously improve the quality of our products and develop new products to meet our customers' needs.Know More +

News dynamics

Our engineers continue to improve product quality, and constantly develop new products to meet customer needs, we take quality and service as the purpose of the enterprise, and continue to work hard

News dynamics

Our engineers continue to improve product quality, and constantly develop new products to meet customer needs, we take quality and service as the purpose of the enterprise, and continue to work hard

Always adhere to the quality of development, quality of survival principle, continue to improve Tianshun products and services

Sincerely welcome the national seed industry colleagues and friends to visit the guidance

02

/

15

News dynamics

08

/

14

News dynamics

10

/

20

News dynamics