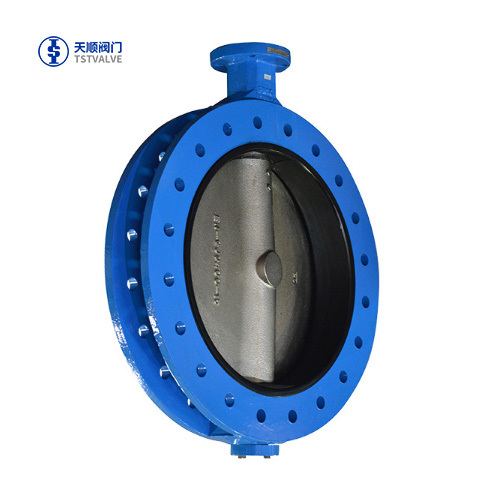

With backrest butterfly valve rubber seat

The rubber seat is a special butterfly valve seat design designed to improve the performance and sealing effect of the butterfly valve.

Key words:

With backrest butterfly valve rubber seat

Classification:

Hotline:

With backrest butterfly valve rubber seat

The rubber seat is a special butterfly valve seat design designed to improve the performance and sealing effect of the butterfly valve.

Structural composition

Rubber material: The main body of the seat is made of rubber material, which has good elasticity and sealing performance.

Backrest design: The seat backrest adopts a two-half circle structure, which helps to enhance the match between the seat and the body and improve axial positioning.

Convex rib and sealing rib: there are two convex ribs on both sides of the seat respectively, which are used to strengthen the sealing effect of the seat and flange. At the same time, the inner wall of the through hole is provided with two sealing bars, which cooperate with the valve stem to provide more reliable sealing protection.

Through hole and concave groove: The inner ring of the valve seat is provided with two through holes in the radial direction. The inner end face of the through hole is spherical shape, and the outer end face is provided with a concave groove. These designs help to reduce fluid resistance and improve valve performance.

Technological advantage

Good sealing performance: The design of rubber material and sealing ribs enables a tight seal between the seat and the stem and flange to effectively prevent fluid leakage.

Enhanced stability: The two semicircular structure of the backrest enables a better match between the seat and the body, improving the stability and reliability of the valve.

Reduce energy consumption: The design of the ribs and sealing ribs helps to reduce fluid resistance, reduce energy consumption, and improve valve efficiency.

Application scenario

The rubber valve seat is widely used in various occasions that require precise control of fluid flow, such as chemical, metallurgy, electric power and other industrial fields. In these areas, valves need to withstand harsh working conditions such as high temperature, high pressure, corrosive media, and the rubber seat of the backrest butterfly valve can meet these requirements with its excellent performance and reliability.

Previous Page

Next Page

Previous Page

No backrest butterfly valve rubber seat

Next Page

Related Products

Consulting